In the rapidly evolving landscape of industrial technology, the integration of artificial intelligence (AI) and edge computing has emerged as a transformative force, particularly in the realm of smart manufacturing. One of the leading players in this field is Geniatech, a company renowned for its innovative solutions that harness the power of edge AI to enhance production processes. This article takes a closer look at Geniatech’s edge AI solutions and their applications in smart manufacturing, exploring how these technologies are reshaping the industry for greater efficiency, productivity, and competitiveness.

Understanding Edge AI and Its Significance in Manufacturing

Edge AI refers to the deployment of artificial intelligence algorithms directly on devices at the edge of the network, rather than relying solely on centralized cloud-based systems. This approach allows for real-time data processing and decision-making closer to the source of information, which is particularly advantageous in manufacturing settings. By analyzing data generated by machinery and production lines on-site, companies can achieve reduced latency, lower bandwidth usage, and enhanced data privacy. This shift from traditional cloud computing to edge computing is pivotal for industries seeking to improve operational efficiency while meeting the demands of modern production environments.

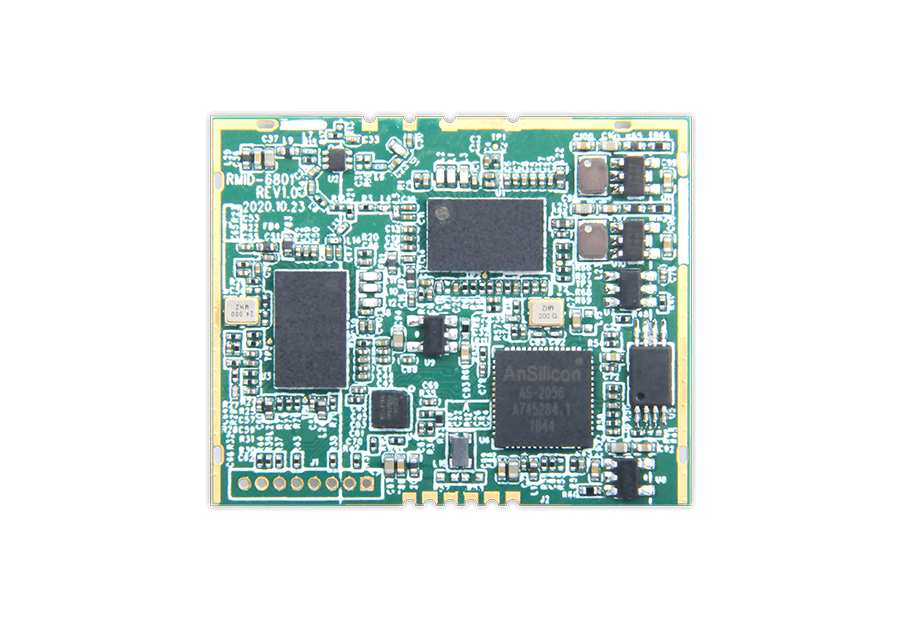

Geniatech’s Innovative Solutions

Geniatech’s edge AI solutions cater to a variety of smart manufacturing needs, providing companies with the tools required to optimize their operations. The core of Geniatech’s offering lies in its platform that integrates state-of-the-art AI algorithms with edge computing capabilities. This platform is designed to facilitate advanced analytics, predictive maintenance, and real-time monitoring of manufacturing processes. By deploying these solutions, companies can not only enhance operational transparency but also identify inefficiencies and potential issues before they escalate into costly downtime.

Applications in Predictive Maintenance

One of the standout applications of Geniatech’s edge AI technology in smart manufacturing is predictive maintenance. Using machine learning algorithms, their systems can analyze data from equipment sensors and identify patterns that indicate wear or impending failure. This foresight allows manufacturers to implement maintenance procedures proactively, rather than following a reactive approach that can lead to unexpected machine breakdowns. The financial implications of predictive maintenance are substantial—they reduce repair costs, minimize production stoppages, and ensure that machinery operates at peak performance.

Enhancing Quality Control

Quality control is another critical area where Geniatech’s edge AI solutions significantly impact smart manufacturing. By leveraging computer vision and deep learning techniques, their technology can inspect products in real-time as they move through the production line. This automated inspection process ensures that defects are identified almost instantaneously, allowing for immediate corrective action. The integration of edge AI in quality control not only enhances product quality but also frees human resources from repetitive inspection tasks, enabling them to focus on more strategic activities within the manufacturing environment.

Streamlining Supply Chain Management

In the context of smart manufacturing, effective supply chain management is crucial for ensuring seamless operations. Geniatech’s solutions provide manufacturers with the ability to monitor and analyze supply chain data in real-time, leading to more informed decision-making. By utilizing edge AI, manufacturers can predict demand fluctuations, optimize inventory levels, and enhance overall supply chain efficiency. This capability is particularly valuable in an era where supply chain disruptions can have far-reaching consequences on production schedules and profitability.

The Role of Data Security

As smart manufacturing increasingly relies on data-driven technologies, data security emerges as a paramount concern. Geniatech addresses this issue through its edge AI solutions by enabling localized data processing, which minimizes the risk of data breaches associated with centralized cloud systems. By keeping sensitive operational data closer to the source and implementing robust encryption and security measures, Geniatech ensures that manufacturers can reap the benefits of AI without compromising their data integrity.

Future Outlook for Geniatech and Smart Manufacturing

As the manufacturing industry continues to evolve, the role of companies like Geniatech in driving technological advancement cannot be overstated. With the increasing commodification of AI and the relentless pursuit of operational excellence, Geniatech’s commitment to innovation positions it as a key player in the future of smart manufacturing. As manufacturers increasingly adopt edge AI solutions, the potential for enhanced productivity, reduced operational costs, and improved product quality will pave the way for a new era of industrial efficiency.

Conclusion

In conclusion, Geniatech’s edge AI solutions are at the forefront of the smart manufacturing revolution, offering tools and technologies that empower companies to optimize their operations in a data-driven world. By leveraging the benefits of real-time analytics, predictive maintenance, quality control enhancements, and secure data management, manufacturers can navigate the complexities of modern production environments with greater agility and sophistication