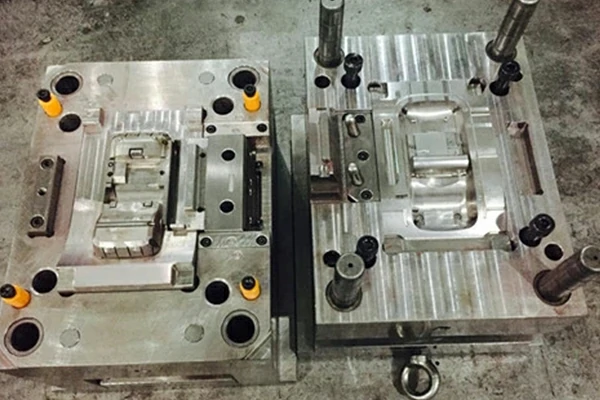

Custom mold manufacturing offers tailored solutions for high-quality products that require specialized tooling. When it comes to creating precision parts with unique shapes or intricate details, custom injection mold tooling is essential for ensuring the highest level of efficiency and quality in the manufacturing process.

The Benefits of Custom Mold Manufacturing

Unlike standard molds, custom injection mold tooling is designed specifically to meet the exact specifications of each individual project. This means that every detail, from the size and shape of the mold cavity to the placement of cooling channels, can be carefully crafted to optimize the production of high-quality parts. By customizing the mold to the specific requirements of a project, manufacturers can ensure that each part is produced with the highest level of precision and accuracy.

Creating Complex Parts with Custom Mold Manufacturing

One of the key advantages of custom mold manufacturing is the ability to produce parts that would be impossible to create with standard molds. Custom injection mold tooling allows manufacturers to create parts with complex geometries, intricate details, and tight tolerances that would be unachievable with off-the-shelf tooling. This opens up a world of possibilities for creating innovative products that push the boundaries of what is possible in manufacturing.

Flexibility and Adaptability in Custom Mold Manufacturing

Custom mold manufacturing also offers the flexibility to adapt to the changing needs of a project. Because custom molds are designed specifically for each project, manufacturers have the ability to easily modify the mold design to accommodate design changes or updates. This means that manufacturers can quickly and efficiently produce high-quality parts without the need for extensive retooling or expensive modifications to the mold.

Quality Control and Precision in Custom Mold Manufacturing

In addition to flexibility, custom mold manufacturing offers unparalleled control over the quality of the finished product. With custom injection mold tooling, manufacturers can optimize every aspect of the production process to ensure that each part meets the highest standards of quality and consistency. This level of precision and control is essential for producing products that meet the strict requirements of industries such as aerospace, automotive, and medical devices.

Cost-Effective Solutions with Custom Mold Manufacturing

Custom mold manufacturing also offers cost-effective solutions for producing high-quality parts. While custom molds may have a higher upfront cost compared to standard molds, the long-term benefits of increased efficiency, reduced waste, and improved quality can lead to significant cost savings over the life of a project. By investing in custom injection mold tooling, manufacturers can ensure that every part is produced with the highest level of quality and consistency, leading to improved customer satisfaction and increased profitability.

Conclusion

In conclusion, custom mold manufacturing offers tailored solutions for producing high-quality products that require specialized tooling. With the ability to create precision parts with unique shapes, complex geometries, and tight tolerances, custom injection mold tooling is essential for manufacturers looking to push the boundaries of what is possible in manufacturing. By investing in custom molds, manufacturers can achieve unparalleled control over the quality of their products, optimize the production process, and ultimately improve their bottom line.