In today’s fast-paced manufacturing industry, it’s essential to have flexible subcontract machining services that can keep up with demanding production schedules and changing design requirements. That’s where subcontract CNC machining comes in. With the latest CNC technology and skilled machinists, subcontract CNC machining offers fast, efficient, and precise component production solutions for a wide range of industries.

Flexibility in Production

One of the key advantages of subcontract CNC machining is its flexibility. Whether you need a small batch of custom components or high-volume production runs, subcontract CNC machining can easily adapt to your specific needs. This makes it an ideal solution for businesses looking to outsource their machining needs without committing to a long-term contract or investment in expensive equipment.

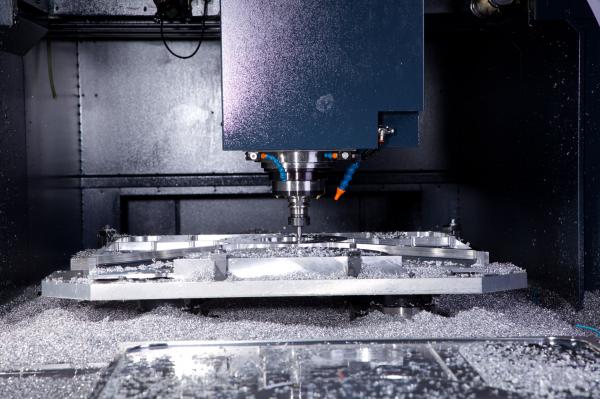

State-of-the-Art CNC Technology

With subcontract CNC machining, you can take advantage of state-of-the-art CNC machines that are capable of producing complex components with high precision and accuracy. This means you can rest assured that your components will meet the highest quality standards and specifications, no matter how intricate or challenging the design may be.

Efficient and Cost-Effective

Another benefit of subcontract CNC machining is its efficiency. By leveraging the expertise of skilled machinists and advanced CNC technology, subcontract machining can significantly reduce lead times and production costs compared to in-house machining operations. This can help you meet tight deadlines, cut down on production downtime, and ultimately improve your bottom line.

Streamlining Manufacturing Processes

Additionally, subcontract CNC machining is a cost-effective solution for businesses looking to streamline their manufacturing processes and focus on core competencies. By outsourcing your machining needs to a trusted subcontractor, you can free up valuable time and resources to concentrate on other areas of your business, such as research and development, marketing, or customer service.

Selecting a Subcontract CNC Machining Partner

When it comes to selecting a subcontract CNC machining partner, it’s crucial to choose a reputable company with a proven track record of delivering high-quality components on time and within budget. Look for a subcontractor that offers a wide range of machining capabilities, including milling, turning, drilling, and grinding, as well as secondary operations such as assembly, finishing, and inspection.

Effective Communication

Communication is key when working with a subcontract CNC machining partner. Be sure to clearly communicate your design requirements, quality standards, and production timelines to ensure that your components are manufactured according to your specifications. Regular updates and progress reports from your subcontractor can also help you stay informed and on top of your project.

Conclusion

In conclusion, subcontract CNC machining offers a flexible, efficient, and cost-effective solution for businesses looking to outsource their machining needs. By partnering with a trusted subcontractor, you can benefit from the latest CNC technology, skilled machinists, and streamlined production processes to produce high-quality components that meet your exact specifications. Whether you need a small batch of custom components or high-volume production runs, subcontract CNC machining can help you meet your manufacturing goals quickly and efficiently.