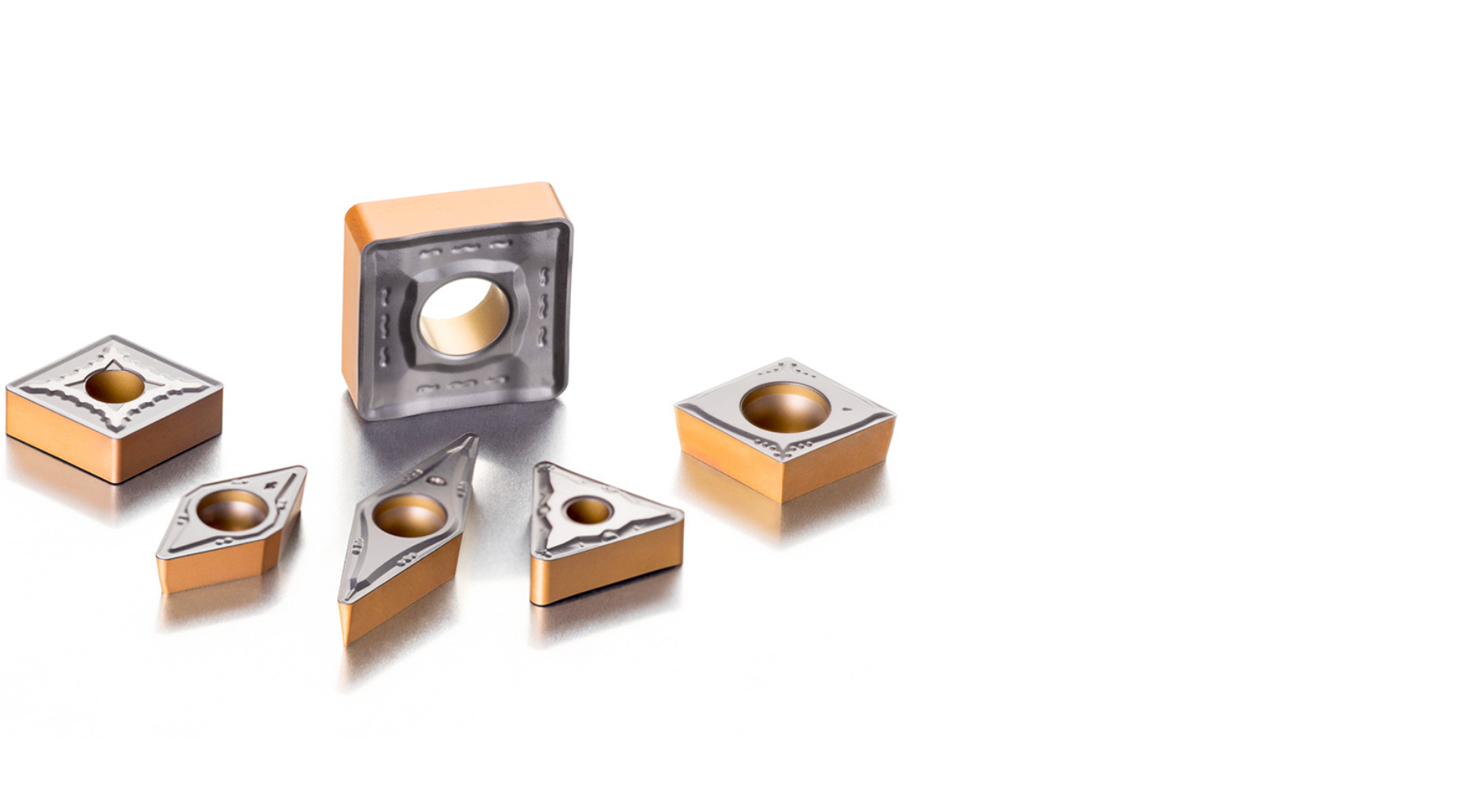

Carbide tooling has been a staple in high-performance machining for many years, offering durability, precision, and reliability in a variety of industrial applications. As technology continues to advance, the future of carbide tooling looks promising, with manufacturers constantly developing new innovations to further improve tool life and performance.

Advanced Coatings for Improved Tool Life

One of the key trends in the future of carbide tooling is the development of advanced coatings that provide increased wear resistance and improved cutting performance. These coatings, such as titanium nitride (TiN), titanium aluminum nitride (TiAlN), and diamond-like carbon (DLC), help extend tool life and maintain sharp cutting edges even under high-speed and high-temperature machining conditions. By incorporating these advanced coatings into carbide tooling designs, manufacturers can offer customers tools that last longer, resulting in reduced downtime and lower overall costs.

Optimized Geometries and Materials for.Enhanced Tool Performance

In addition to advanced coatings, the future of carbide tooling also includes the use of advanced geometries and materials to further enhance tool performance. By optimizing tool designs for specific machining applications, manufacturers can improve cutting efficiency, reduce cutting forces, and minimize tool wear. For example, the development of variable helix end mills with multiple flute geometries allows for smoother cutting operations and improved chip evacuation, leading to longer tool life and better surface finish quality.

New Materials for High-Performance Machining

Furthermore, the use of new materials, such as ultrafine grain carbide and nanocrystalline diamond, are helping to push the boundaries of high-performance machining even further. These materials offer greater hardness, strength, and thermal stability compared to traditional carbide grades, making them ideal for cutting challenging materials like aerospace alloys, composites, and hardened steels. With these advanced materials, carbide tooling manufacturers can provide customers with tools that can withstand the most demanding machining applications with ease.

Integration of Smart Technologies

Another key aspect of the future of carbide tooling is the integration of smart technologies, such as sensors and data analytics, to monitor tool performance in real-time. By collecting data on cutting forces, temperature, and tool wear, manufacturers can identify potential issues before they escalate, allowing for proactive maintenance and tool replacement. This predictive maintenance approach not only helps to minimize unexpected downtime but also enables customers to optimize their machining processes for maximum efficiency and cost savings.

Conclusion

Overall, the future of carbide tooling in high-performance machining is bright, with continued advancements in coatings, geometries, materials, and smart technologies leading to improved tool life, reduced downtime, and lower costs for manufacturers. By staying at the forefront of these developments and embracing the latest innovations in carbide tooling, businesses can maximize their productivity and profitability in the ever-evolving world of precision machining.